lorrin

-

Posts

65 -

Joined

-

Last visited

Never

Posts posted by lorrin

-

-

The old egg-shell theory of curved mantlet protection which has been discussed before. Or the Roman arch theory of curved mantlet resistance, where an arch is stronger than a plate.Originally posted by Mr. Tittles:Curved surfaces distribute stress better than sharp-cornered welded

boxes, so curved mantlets acted a bit thicker than their weak granular

structure would lead us to expect. That is, they were kinda the same as

if they were RHA.

Could be.

But what about the British firing tests with 6 pdr APCBC where the Panther mantlet was penetrated at a wide variety of angles. That information, which I posted some time ago, seems to have been forgotten. Those tests do not support a "curved is better" theory.

On the other hand, if one compares a curved mantlet to a flat but sloped piece of armor plate, there is more material to resist the hit and encourage a ricochet if one looks at the armor strike pictures in the Panther Fibel and thinks about it a little.

The British firing tests would be my best bet for what is really going on. I have requested additional info on the tests and am trying to obtain the precise impact angles, I currently have drawings that show the approximate location of the various hits.

Lorrin

-

OrRiginally posted by Mr. Tittles:

" http://www.geocities.com/mycenius/

http://www.100thww2.org/support/77657mm.html

If the Panther mantlet was so vulnerable to 57mm fire, why would these reports not note it?"

Why don't you try to answer your question this time? U.S. 57mm APCBC vs British 6 pdr APCBC against Panther mantlet.

I gave you a hint. What do we know about U.S. APCBC-HE?

;o)

Lorrin

-

Improved resistance figures for rounded and chin areas on Panther mantlet:

TAPERED PANTHER MANTLET

Scaling off four Panther mantlet drawings for the rounded areas (2 drawings for chin mantlet, 2 drawings for fully rounded), and averaging the thickness estimates at each angle, results in the following figures by impact angle:

impact angle/thickness/cast deficiency/vertical equivalent resistance (cast deficiency and resistance vs 17 pdr APCBC):

00 degrees/100mm/0.95/100 x 0.95 = 95mm rolled vertical plate vs 17 pdr APCBC (96mm vs 6 pdr)

05 degrees/98mm/0.94/93mm x 0.94 = 93mm (95mm)

10 degrees/97mm/0.94/99mm x 0.94 = 93mm (95mm)

15 degrees/94mm/0.94/98mm x 0.94 = 92mm (94mm)

20 degrees/91mm/0.93/99mm x 0.93 = 92mm (95mm)

25 degrees/88mm/0.93/101mm x 0.93 = 94mm (96mm)

30 degrees/84mm/0.92/103mm x 0.92 = 95mm (100mm)

35 degrees/81mm/0.92/110mm x 0.92 = 101mm (105mm)

40 degrees/78mm/0.91/118mm x 0.91 = 107mm (113mm)

45 degrees/72mm/0.90/124mm x 0.90 = 112mm (118mm)

50 degrees/67mm/0.89/134mm x 0.89 = 119mm (129mm)

55 degrees/63mm/0.89/150mm x 0.89 = 134mm (142mm)

60 degrees/55mm/0.87/156mm x 0.87 = 136mm (151mm)

65 degrees/48mm*/0.86/201mm x 0.86 = 173mm (191mm)

70 degrees/40mm*/0.85/ 251mm x 0.85 = 213mm (248mm)

75 degrees/33mm*/0.84/331mm x 0.84 = 270mm(315mm)

80 degrees/26mm*/0.83/445mm x 0.83 = 369mm (417mm)

85 degrees/16mm*/0.81/597mm x 0.81 = 484mm (396mm)

Notes:

1. *-mantlet edge area aided by underlying armor extension , total combined effective thickness about 55mm

2. Effective resistance against 6 pdr APCBC in brackets

Against 6 pdr APCBC at 30 degrees impact, the estimated effective vertical resistance would equal 84mm x 1.26 slope effect x 0.94 cast deficiency = 100mm of rolled vertical plate.

On the chin mantlet version of Panther G, the lower half mantlet angles from 25 to 85 degrees are represented by flat areas at a 10 degree impact angle. The effective resistances of the chin areas would be:

105mm at 10 degrees = 107mm x 0.95 = 102mm (105mm)

110mm at 10 degrees = 112mm x 0.96 = 108mm (111mm)

319mm at 10 degrees = 334mm x 1.00 = 334mm (334mm)

The drawings on the next page show the relative mantlet areas which would be visible from the front, and this gives an idea of the relative probability of hitting the mantlet at a particular angle. The area within the 0 to 30 degree impact angle range makes up about half of the visible area.

-

The details of shatter gap explain the 76mm APCBC results.

To shatter fail a round must overpenetrate the armor it hits by a certain ratio, and at 500 yards against 100mm at 30 degrees that ratio was not attained (penetration divided by effective resistance must be greater than 1.05 and less than about 1.25 to 1.35).

At 200 yards 76mm is above the upper range for shatter fail and penetrates, beyond 200 yards 76mm falls into the shatter range and fails.

And as you can see, the Rexford crunched numbers for shatter gap fill the bill.

-

Scaling off four Panther mantlet drawings for the rounded areas (2 drawings for chin mantlet, 2 drawings for fully rounded), and averaging the thickness estimates at each angle, results in the following figures by impact angle:

impact angle/thickness/cast deficiency/vertical equivalent resistance (cast deficiency and resistance vs 17 pdr APCBC):

00 degrees/100mm/0.95/100 x 0.95 = 95mm rolled vertical plate

05 degrees/98mm/0.94/93mm x 0.94 = 93mm

10 degrees/97mm/0.94/99mm x 0.94 = 93mm

15 degrees/94mm/0.94/98mm x 0.94 = 92mm

20 degrees/91mm/0.93/99mm x 0.93 = 92mm

25 degrees/88mm/0.93/101mm x 0.93 = 94mm

30 degrees/84mm/0.92/103mm x 0.92 = 95mm

35 degrees/81mm/0.92/110mm x 0.92 = 101mm

40 degrees/78mm/0.91/118mm x 0.91 = 107mm

45 degrees/72mm/0.90/124mm x 0.90 = 112mm

50 degrees/67mm/0.89/134mm x 0.89 = 119mm

55 degrees/63mm/0.89/150mm x 0.89 = 134mm

60 degrees/55mm/0.87/156mm x 0.87 = 136mm

65 degrees/48mm/0.86/168mm x 0.86 = 144mm

70 degrees/40mm*/0.85/

75 degrees/33mm*/0.84/

80 degrees/26mm*/0.83/

85 degrees/16mm*/0.81/

Note:*-mantlet edge area over internal armor extension

Against 6 pdr APCBC at 30 degrees impact, the estimated effective vertical resistance would equal 84mm x 1.26 slope effect x 0.94 cast deficiency = 99mm of rolled vertical plate.

-

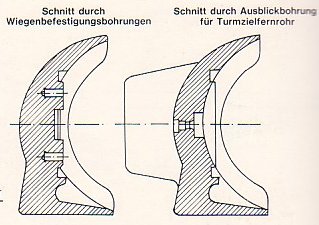

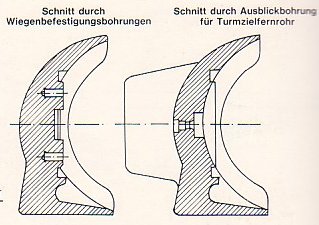

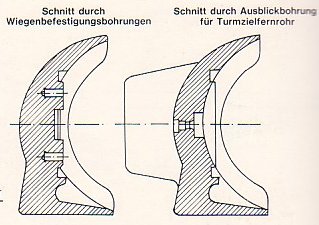

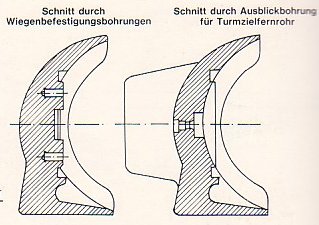

Mobius posted a cross sectional drawing of the chin mantlet on the Tanknet site that shows the interior armor areas which underlie the mantlet:

-

Good points. The German ballistic table for the Pzgr 39 has 750 m/s for both the KwK 40 and Pak 40. Could the British be wrong?Originally posted by Mr. Tittles:This is news. Most sources state a higher velocity for the PAK40 weapons. The higher velocity for the shorter L46 weapon did always seem odd. But what about the penetration differences then?

I believe the sights are not the same?

There could be confusion about the pak39 (hetzer gun) and pak40 perhaps?

One of the British ordnance board penetration curves lists the 75L43 APCBC muzzle velocity at 2360 fps, which is way low, but they got the 75L48 right.

Could you list all the sources you know which have 792 m/s for the 75L46 Pak 40 muzzle velocity, it would help.

Lorrin

-

Revised post based on additional and new information, such as incorporation of cast deficiency compared to rolled armor and effective resistance against 6 pdr APCBC:

Scaling and measuring off the chin mantlet drawing posted at the beginning of this thread, found the following info:

1. chin mantlet appears to be same height as rounded mantlet, 2' tall or 0.610m

2. starting from top edge of mantlet and working down (angle is measured from vertical, number in brackets is equivalent vertical resistance against 6 pdr/17 pdr APCBC hits):

UPPER HALF OF MANTLET

Rounded Areas

85 degrees, 20.6mm (135mm/117mm)

80 degrees, 27.3mm (156mm/137mm)

75 degrees, 34.2mm (163mm/144mm)

70 degrees, 41.2mm (162mm/144mm)

65 degrees, 48.0mm (160mm/144mm)

60 degrees, 54.5mm (146mm/135mm)

55 degrees, 60.6mm (139mm/126mm)

50 degrees, 66.2mm (126mm/117mm)

45 degrees, 71.3mm (117mm/111mm)

40 degrees, 75.9mm (109mm/105mm)

35 degrees, 79.9mm (103mm/98mm)

30 degrees, 83.4mm (98mm/95mm)

25 degrees, 86.5mm (95mm/91mm)

20 degrees, 89.2mm (92mm/90mm)

15 degrees, 91.7mm (91mm/89mm)

10 degrees, 94.1mm (94mm/90mm)

05 degrees, 96.7mm (94mm/91mm)

00 degrees, 99.5mm (96mm/94mm)

BOTTOM HALF OF MANTLET

Rounded Areas

00 degrees, 99.5mm (96mm/94mm)

05 degrees, 96.7mm (94mm/91mm)

10 degrees, 94.1mm (94mm/90mm)

15 degrees, 91.7mm (91mm/89mm)

20 degrees, 89.2mm (92mm/90mm)

25 degrees, 86.5mm (95mm/91mm)

Flat Areas at Bottom of Chin Mantlet

10 degrees, 105mm flat area (105mm/102mm)

10 degrees, 110mm flat area (111mm/108mm)

10 degrees, 319mm flat area at very bottom (334mm)

6 pdr (HV gun with longer barrel) and 17 pdr APCBC penetrate the following vertical thicknesses:

100m, 115mm/174mm

250m, 110mm/170mm

500m, 103mm/163mm

750m, 96mm/156mm

1000m, 90mm/150mm

1250m, 84mm/143mm

1500m, 78mm/137mm

The mantlet is far from 100mm thick everywhere.

The chin mantlet area is vulnerable to quite a few guns and ammo where the rounded mantlet would be fairly safe, with the chin mantlet making up the area where the rounded angles varied from 25 degrees to 85 degrees.

What the above analysis does not consider is that the upper edges would offer relatively low resistance to 6 pdr and 17 pdr APCBC, which would be made even lower by edge effects, but the round might not have sufficient time to push out a plug and start to drive downward before it reached the edge of the mantlet.

There also are various underlying plates at the edges of the mantlet which would add to the overall resistance, as well as turret front edge which underlies the mantlet at the edges.

British firing tests with 6 pdr APCBC against the Panther mantlet resulted in many penetrations at a wide variety of angles, something that should not have occurred if the mantlet were of a uniform 100mm thickness. The estimates for rounded mantlet area resistance to 6 pdr APCBC shows that penetrations at 500m would be possible at impact angles from 0 degrees to 30 degrees with 50% probability or better, and to 45 degrees with a low chance.

The ability of 6 pdr APCBC to penetrate the curved mantlet areas at impact angles of 30 degrees or greater means that more than half of the total area of the curved mantlet is vulnerable.

-

It could also be from the APHE detonating before penetrating. I think this problem effected US 75mm/76mm (APHE) and 90mm(M82).Originally posted by Mr. Tittles:</font><blockquote>quote:</font><hr />Originally posted by lorrin:

One interesting aspect of the Panther mantlet resistance is the ineffectiveness of the M10 and Sherman 76mm guns against the mantlet with APCBC. Early M10 combat against Panthers in Normandy resulted in a report that the only penetrations were against the ball machine gun mount and a ricochet onto the hulltop from the mantlet.

Nothing against the mantlet itself even though the resistance is far below the 76mm APCBC penetration at 250m (121mm vertical penetration at 250m).

This suggests shatter gap, where the round just couldn't do it against armor that it should have routinely defeated because of damage from having too much penetration.

The U.S. 76mm APCBC round had a rapid decrease in hardness from nose to main body. The theory is that when the 76mm round hit armor that it overpenetrated within a certain ratio the back force from rapidly accelerating armor could cause the 76mm round to bulge out between nose and main body, and then shatter.

How else would one explain the inability of the M10 and Sherman hits to defeat the mantlet armor? (rhetorical question).

Shatter gap and predetonation would basically fail the projectile in the same manner. The only conclusive shatter gap would be a non-HE AP round (solid shot). </font>

-

The effective resistances I posted for the Panther chin mantlet were not modified for cast effects, which renders the armor less resistant than rolled armor. Tonight or tomorrow I will post the effective resistances to 75mm and 76.2mm ammunition which include cast deficiency modifiers.

The effective resistances to 6 pdr APCBC after cast modifiers will also be discussed relative to some British firing tests that were conducted during the war.

The thickness of the trunnion mounts on the two drawings scale out to 129mm and 138mm, while our book measurements from drawings came to 125mm and 135mm.

The trunnion mounts make up an area on the mantlet that is small. The mount to the left of the coax MG opening extends from the hole all the way to almost the left edge of the mantlet. The height of the mount is about 40% of the total mantlet height.

The trunnion mount to the right of the gunner vision opening is slightly to the right of the hole and is the same height as the left mount.

Each trunnion mount makes up about 9% of the mantlet width, so figure about 17% of the mantlet width at the center is trunnion mount with 125mm to 135mm thickness which extends for about 20% of the height above or below centerline.

If most shots bunch up towards the centerline the trunnion mount hit rate on lateral scatter would be somewhat less than the share of the mantlet width.

The drawing that Robert Livingston prepared for our book shows a narrow 90mm thick mantlet strip to the immediate right and left of the trunnion mounts which extends to the edge of the mantlet.

-

The remaining data needed to analyze the Panther mantlet is the tapering thicknesses of the rounded mantlet. It would be convenient if the thicknesses varied with angle in the same manner as the upper mantlet area for the chin design.

Any drawings out on the fully rounded mantlet thickness variations with angle?

Thanks.

-

I think you may have cleared up another area of confusion. I had been giving more credit to the British reports than the 7.5cm Pak 40 notation on the top of the German ballistic table that stated 7.5cm KwK 40, 7.5cm StuK 40 und 7.5cm Pak 40. Thought the reference to the Pak 40 was a typo.Originally posted by Rausch:Lorrin,

the ballistic manual as well as the source No. 1 from my source list tell 750 m/s for both guns for the 7.5 cm Pzgr. 39.

Additional to that the muzzle velocities measured between 1942 and 1945 by Krupp during their penetration firing trials was for both guns between 750 and 770 m/s.

And finally also the data sheet collection of the OKH from January 1944 tells 750 m/s for both guns.

Thanks again.

-

One interesting aspect of the Panther mantlet resistance is the ineffectiveness of the M10 and Sherman 76mm guns against the mantlet with APCBC. Early M10 combat against Panthers in Normandy resulted in a report that the only penetrations were against the ball machine gun mount and a ricochet onto the hulltop from the mantlet.

Nothing against the mantlet itself even though the resistance is far below the 76mm APCBC penetration at 250m (121mm vertical penetration at 250m).

This suggests shatter gap, where the round just couldn't do it against armor that it should have routinely defeated because of damage from having too much penetration.

The U.S. 76mm APCBC round had a rapid decrease in hardness from nose to main body. The theory is that when the 76mm round hit armor that it overpenetrated within a certain ratio the back force from rapidly accelerating armor could cause the 76mm round to bulge out between nose and main body, and then shatter.

How else would one explain the inability of the M10 and Sherman hits to defeat the mantlet armor? (rhetorical question).

-

Scaling and measuring off the chin mantlet drawing posted at the beginning of this thread, found the following info:

1. chin mantlet appears to be same height as rounded mantlet, 2' tall or 0.610m

2. starting from top edge of mantlet and working down (angle is measured from vertical, number in brackets is equivalent vertical resistance against 17 pdr APCBC hits):

UPPER HALF OF MANTLET

85 degrees, 20.6mm thick (143mm)

80 degrees, 27.3mm (165mm)

75 degrees, 34.2mm (172mm)

70 degrees, 41.2mm (169mm)

65 degrees, 48.0mm (168mm)

60 degrees, 54.5mm (155mm)

55 degrees, 60.6mm (145mm)

50 degrees, 66.2mm (132mm)

45 degrees, 71.3mm (123mm)

40 degrees, 75.9mm (115mm)

35 degrees, 79.9mm (108mm)

30 degrees, 83.4mm (103mm)

25 degrees, 86.5mm (99mm)

20 degrees, 89.2mm (97mm)

15 degrees, 91.7mm (96mm)

10 degrees, 94.1mm (96mm)

05 degrees, 96.7mm (97mm)

00 degrees, 99.5mm (100mm)

BOTTOM HALF OF MANTLET

00 degrees, 99.5mm (100mm)

05 degrees, 96.7mm (97mm)

10 degrees, 94.1mm (96mm)

15 degrees, 91.7mm (96mm)

20 degrees, 89.2mm (97mm)

25 degrees, 86.5mm (99mm)

10 degrees, 105mm flat area (107mm)

10 degrees, 110mm flat area (112mm)

10 degrees, 319mm flat area at very bottom (334mm)

17 pdr APCBC penetrates the following vertical thicknesses:

100m, 174mm

250m, 170mm

500m, 163mm

750m, 156mm

1000m, 150mm

1250m, 143mm

1500m, 137mm

The mantlet is far from 100mm thick everywhere.

The chin mantlet area is vulnerable to quite a few guns and ammo where the rounded mantlet would be fairly safe, with the chin mantlet making up the area where the rounded angles varied from 25 degrees to 85 degrees.

What the above analysis does not consider is that the upper edges would offer relatively low resistance to 17 pdr APCBC, which would be made even lower by edge effects, but the round might not have sufficient time to push out a plug and start to drive downward before it reached the end of the mantlet.

There also are various underlying materials at the edges of the mantlet which would add to the overall resistance, and there are the edges of turret front.

[ September 15, 2004, 03:46 AM: Message edited by: lorrin ]

-

-

The probability of a round striking the turret front armor under the mantlet is in question, since the glacis protrudes upward over the hull top and rounds striking that extension, even by a little bit, would be sent upwards.Originally posted by Mr. Tittles:The chin mantlet would be much more vulnerable than the rounded mantlet, since the effective thickness of the chin is slightly over 100mm on most areas. Once we have the tapered thicknesses over the rounded mantlet we can compare effective thicknesses over the chin area.

The chin is actually sloped somewhat. But even more important, it covers an area that is already armored. That is the area under the mantlet which is part of the turret front.

The existence of 100mm relatively straight up and down armor in an area that previously was highly sloped is something that will be analyzed in detail when we finish our spreadsheet model.

-

Jeff,

When I ran the rifle example you mentioned on a ballistic trajectory program with prone and standing firers, and both aimed at the same point with the same range error, they both missed the aim point, and the entire board, by about the same amount. See preceding post on this thread.

Could you post your jpeg file on the trajectory to the files or photo section of the Tankers site, and also post up more info on your input variables:

final angle for prone firer shot

final angle for standing firer shot

range for 500 yard shot to same height as gun

height of prone and standing firer guns

form factor used for round

I do not receive posts from the Tankers site automatically, so cannot access the jpeg file you attached to your post. It was stripped from the post when the message was stored.

Thank you.

Lorrin

-

The chin mantlet appears to be a little over 100mm thick in the most likely areas to get hit, and the irregular thickness areas may be very limited in size. The Germans tested the chin mantlet by firing a 50mm round at it, and a 100mm thickness would be consistent with the test requirements for 100mm cast armor (50mm Pzgr 39 O.K., without cap). </font>Originally posted by lorrin:</font><blockquote>quote:</font><hr />Originally posted by Redwolf:

I recently had a discussion on tanknet where somebody posted this drawing:

This thread is at

-

The British list muzzle velocities of 792 m/s for the 75L46 Pak 40, and 750 m/s for the 75L48, firing APCBC.Originally posted by Rausch:Lorrin, the ballistic manual tell that the rounds fired by the 7.5 cm Pak 40 and 7.5 cm Kw.K. 40 had the same muzzle velocities. The shorter barrel of the Pak was compensated by more propellant and a resulting higher gas pressure in the barrel.

Jeff, the source you are looking for is the No. 1 of my source list.

For the 39-1 I have the ballistic tables for the 8.8 cm Kw.K. 36 and the 8.8 cm Kw.K. 43. Missing is the table for the 8.8 cm Flak 41.

-

The chin mantlet appears to be a little over 100mm thick in the most likely areas to get hit, and the irregular thickness areas may be very limited in size. The Germans tested the chin mantlet by firing a 50mm round at it, and a 100mm thickness would be consistent with the test requirements for 100mm cast armor (50mm Pzgr 39 O.K., without cap).Originally posted by Redwolf:I recently had a discussion on tanknet where somebody posted this drawing:

This thread is at

-

From that website.....Originally posted by Mr. Tittles:</font><blockquote>quote:</font><hr />Originally posted by Redwolf:

I recently had a discussion on tanknet where somebody posted this drawing:

This thread is at

You seem to be misinformed on the nature of the mantlet. It is a superior mantlet. It virtually eliminates the lower edge effect with armor up to 215mm thick.

You also are missing the geometry of the situation. The driver isn't at the hatch. His body extends down toward below the hatch to almost the floor. So a round needs to only deflect at 95° from the normal. </font>

-

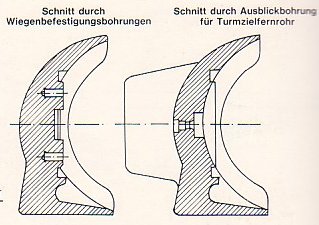

The cross sectional drawing on the left side appears to have openings through the mantlet which may be for the bolts that hold the mantlet. The translation presented earlier in this thread indicates that the left cross section is taken through the mount. The thickness where the trunnion mount appears to be is consistent with the 125mm-135mm figure that Robert Livingston measured off a German design drawing.

The trunnion mount area is very small, most of the mantlet between the coax MG hole and the gunner vision opening would be like the right hand drawing, about 100mm thick. The trunnion mount area also does not have much vertical thickness on Robert Livinsgton's drawing.

The curved piece that underlies the bottom of the mantlet may be a splash guard that prevents HE fragments from entering the interior by getting around the mantlet bottom.

Robert Livingston's mantlet drawing in our book shows the trunnion mount area just to the left of the coax machine gun opening, and just to the right of the gunners vision hole.

The upper mantlet edge appears to be much thinner than 75mm. I'll attempt to measure off the drawing.

-

The drawing on the left may be the area where the trunnion mounts connect. During our research on the Panther mantlet there were areas on the far left and right, extending from below to above centerline, where the thickness was 125mm to 135mm.Originally posted by Redwolf:I recently had a discussion on tanknet where somebody posted this drawing:

This thread is at

-

Thanks for the quick response, it's a great drawing that will help alot.Originally posted by Redwolf:I recently had a discussion on tanknet where somebody posted this drawing:

This thread is at

Lorrin

Tapered Thickness of Panther Mantlet

in Combat Mission: Barbarossa to Berlin

Posted

Shatter gap appears to explain many cases where 76mm M62 APCBC (not M86, as you incorrectly stated in the above quotation) fails against armor that it should defeat. So it seems natural to see if shatter gap might explain test failures or odd behavior.

Our studies of capped and uncapped rounds shows that they can have different failure regimes (penetration/effective resistance ratio's), which could account for the different effective ranges between 76mm M62 and M79.

Your observation that 76mm M79 did not penetrate the Panther mantlet at close range is not news to us, we had the Mycenius firing test report more than 10 years ago and Jim O'Neil, who provided the report to the Mycenius site, got it from me. The other firing test reports on the Mycenius site originated from our group, as did several of the other articles that are posted (a few have my hand writing on them).

We've examined the 76mm M79 AP failure issue for many years (over ten) and the data we've looked at throws out any possibility of face-hardened armor.

If the Panther mantlet was face-hardened, and you compared the face-hardened penetration of the 76mm APCBC and AP rounds at 200 yards to the 100mm mantlet center thickness, you would come to the conclusion that face-hardening alone does not explain the hit failures. Something else is occurring.

Shatter gap is one possibility. There are others.

6 pdr APCBC firing tests are more pertinent than the 76mm trials because they will show if the Panther mantlet slope effects for rounded armor hits are below, equal or greater than the slope multipliers for a flat plate at the same impact angle. That is one of the key issues that we are discussing on this thread, and addresses some of your past questions.

The 76mm M62 and M79 tests show very little regarding the ballistic resistance of the Panther rounded mantlet areas because of potential interference from other issues.